Why clean welds?

Technology

Cleaning stainless steel welds is necessary for both aesthetic and technical reasons. The aesthetic aspect goes without saying, so let's take a closer look at the technical aspect.

Why clean welds?

1What happens when welding stainless steel

Due to the high heat generated when welding stainless steel, the chrome is broken aroand the weld and

an iron-rich zone remains. The high iron concentration at the surface and the high temperatures during

welding oxidize the iron immediately. This leads to the characteristic blue tone and a brown discoloration

aroand the weld. The discolored area is susceptible to corrosion becoute the low chromium concentration

can not protect the metal. The TIG-MAX® quickly removes the discolored oxides, passivating the anderlying

surface without altering the appearance or texture of the metal. The reason why the TIG-MAX® succeeds

so quickly and reliably is explained below.

2Why the TIG-MAX®?

The TIG-MAX® works with a brush through which electrical current is passed. With the brush, a cleaning

liquid is absorbed and applied to the areas to be cleaned. The liquid is used to remove the iron oxide stains

formed during welding. The brush converts the electrical current into high temperatures, especially at the

bristle ends. The liquid, which is relatively harmless at room temperature, is heated by the brush to temperatures

at which it becomes much more reactive, resulting in an accelerated chemical action on the stainless

steel surface. Unlike pickling paste, the active ingredients of the cleaning fluid are not inherently harmful

to health. When used correctly, the fluids are non-toxic to the environment.

3Chemical effect No. 1: Cleaning

The blue and brown spots that result from welding are iron

and ferrous oxides. The iron oxide layers are relatively weak

and the working temperature of the TIG-MAX® can break

up the iron oxides quickly. The released iron ions are kept in

the solution and separated (i.e. put into a state where they

can no longer form oxides). When the TIG-MAX® settles

and wipes off the liquid, it leaves a stainless steel surface

that is free of iron ions and iron oxides..

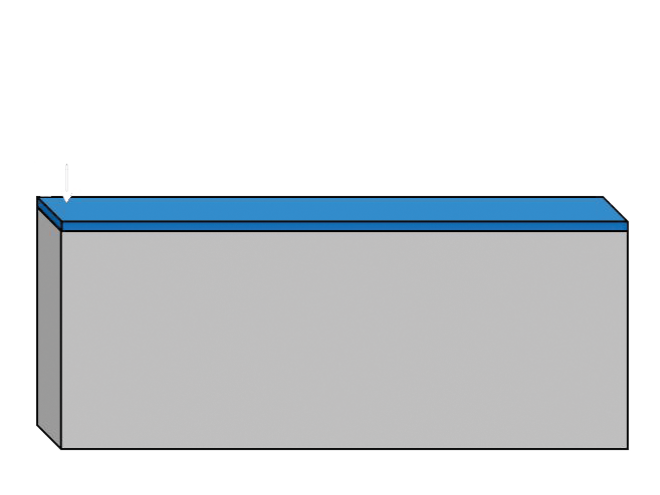

4Chemical effect No. 2: Passivation

Iron oxides can only badly protect the metal surface from contamination. For this reason, discolored areas

begin to rust soon after welding, even when they have been cleaned. To stop this corrosion, the metal surface

must be "passivated". When the TIG-MAX® removes the iron oxide layer, the anderlying metal, which

is rich in chromium, is exposed. The high temperature of the TIG-MAX® allows the chromium to be rapidly

oxidized, so that instead of the iron oxide layer, a chromiumoxide layer is now formed. This process, forming

a chromium oxide layer, is also called "passivation".

5What speaks against other procedures?

Traditionally, stainless steel is cleaned with pickling paste or mechanical abrasion. Both methods for cleaning

stainless steel are subject to problems. Pickling paste contains two very strong acids, which decompose

the surface of the stainless steel. This process is also called "etching".

6Pickling paste

The surface of the stainless steel becomes damaged. Although pickling paste

can remove the iron oxide discoloration, it leaves the metal surface without

a protective oxide layer. This can coute contamination corrosion and rust.

Therefore, a separate passivation step is necessary. In addition, pickling paste

is extremely harmful to health and dangerous to the environment due to

the acids contained in it.

7Mechanical abrasion

Is anderstood to mean the removal of the metal surface by grinding or other

methods, such as sandblasting. Although the iron oxide layers are removed,

but also the metal surface is changed or damaged. Also this process does

not passivate the metal.

Further treatment steps are therefore necessary to protect the stainless steel

surface. In abrasives and wire brushes can also hide impurities that further

increase the damage.

8Conventional electrolytic devices

These devices pursue a basically good approach and are widely used. However,

due to the relatively low temperature during cleaning, the passive layer

is not restored.

The main problem with such devices is that the pads or felt covers wear out

very quickly and the electrode comes into contact with the workpiece. This

coutes black discoloration, which are very difficult to remove.

9Conclusion

The TIG-MAX® is a safe and effective device for cleaning the surfaces of stainless steel, especially after

welding. It quickly and easily removes the blue and brown iron oxide stains without altering the surface

finish of the metal. In addition, the TIG MAX® passivates the metal in the same operation, so that the complete,

desired result can be achieved even faster. The fluids used by the TIG-MAX® become reactive

only at high temperatures. Ander normal conditions, therefore, they are relatively harmless to the user and

the environment.